Denounce with righteous indignation and dislike men who are beguiled and demoralized by the charms pleasure moment so blinded desire that they cannot foresee the pain and trouble.

Read MoreWelcome to Futura where we redefine possibilities through Innovative Technology-Based Solutions!

24/7 Customer support

The less water you use, the less runoff and wastewater that eventually end up in the ocean.

The less water you use, the less runoff and wastewater that eventually end up in the ocean.

Read MoreExperience Team

The less water you use, the less runoff and wastewater that eventually end up in the ocean.

The less water you use, the less runoff and wastewater that eventually end up in the ocean.

Read MoreSmart solutions

The less water you use, the less runoff and wastewater that eventually end up in the ocean.

The less water you use, the less runoff and wastewater that eventually end up in the ocean.

Read More

Claims of duty

Certain circumstances seds owing to the claims duty our righteous indignation and so beguiled.

Futura as the name implicates- technologies and advancements of the future. We are ex-industry stalwarts with the purpose and vision of bringing specialized knowledge, value added products, services and solutions to you which will help your businesses grow and be profitable & sustainable.

Many of our process technologies are a result of Innovation, Process Development, Research and Strategic Technology Tie-ups with International Companies with R&D facilities having core expertise in the subject field. We have associations with many industry leading solutions and service providers to provide and end-to-end and seamless delivery for your needs.

Accepted always

To take a trivial example, which of us ever undertakes get laborious physical exercise.

Futura Technologies exclusively focuses on various innovative technology-based solutions for the process, industrial and manufacturing sectors. Our expertise is in bringing specialized knowledge, value added products, services and solutions to our clients which help them grow and be profitable & sustainable.

Water Solution

→ Wastewater Treatment Solutions (ETP & STP)

→ Recycle Water for Re-use UF, NF, RO, MBR and MEE / MVRE

→ Raw Water and Utility Water Treatment

→ Anti-Scaling and Anti-Fouling Solutions

→ Manufacture and supply of Water Treatment ChemicalsColor removal, Acrylamides, Coagulants, Flocculants

→ Rainwater Harvesting and Ground Water Solutions (RHaGS)

Digital Technologies

→ Digital Twins using 3D Laser Scanning Technology

→ Revamps and Brownfield Modifications

→ Photogrammetry and GIS Mapping Solutions

→ VR / AR applications for Manufacturing

→ Industry 4.0 and IIOT Applications

Cyber Security & IT Solutions

→ Cyber Engineering and Cyber Security Solutions

→ Facility Risk Management Applications

→ Web / Mobile Applications for Upkeep of Operations and Maintenance of Manufacturing Plants

→ Asset Performance Management

Plastics & Polymers

Coal Washing / Handling

Pharmaceuticals and Bulk Drugs

Common Effluent Treatment Plants (CETPs)

Agrochemicals

Food & Beverage

Common Effluent Treatment Plants (CETPs)

Leather & Tanneries

Pulp & Paper

Textiles

& Textile Dyes

Dyes, Paints, Pigments and Inks

Metals & Mining

Petrochemicals

Dyes, Paints, Pigments and Inks

Produced Water (Oil & Gas)

Glass & Ceramics

Chemicals & Specialty Chemicals

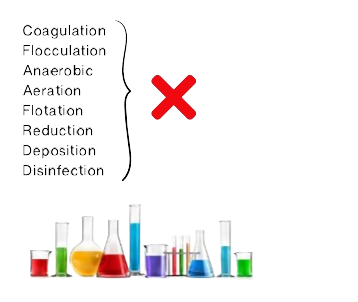

Modular Unit Easily Add Capacity

Modular Units- No Need to Install Full Capacity at Once

Least Manpower Requirement

Simple Switch ON / Switch OFF Operation

OPEX and CAPEX of Actual Generation

Don't Pay Now for Future Capacity

Scientific Approach to each effluent

Step by step approach to a feasible outcome

Pipeline Reactors Installation Possible

For Low HRT (<10 min) Entire ETP Plant in Pipeline

Treated Effluent pH Tends to Swing Neutral

Lesser Chemicals Required. Simpler Downstream Systems

100% Modular Skid Based Plants

Install Anywhere. Go vertical to save floor space

Fully Automated Plants with IIOT

PLC / Microcontroller Based Operation

NO Civil Works

Needed

Only PCC and Footings Required

Less than 40% Sludge Generated

Compared to Sludge in Conventional Systems

Polishing of Treated Effluent before UF NF RO

Removes Silica, Hardness, Turbidity and TSS easily

Ultra-Compact & Portable Plant

Less Than 10% Floor Space Compared to Conventional Systems

HO Enabler Catalysts Have Very Long Life

No Frequent Adjustments or Replacements Needed

8-10 Weeks Delivery of Commercial Plant

10 Days for Installation & Commissioning

Complete ZLD Recycle & Reuse Water

PLC / Microcontroller Based Operation

Effluent HRT in

Minutes & Hours

Not in Number of Days like Conventional Systems

Destroys Bacteria,

Viruses & Cysts

Removes all Fecal Coliform / Algae / Biological Growth. Automatic Disinfection

No Operational Skills Required

No MLSS / No FM Ratio Calculations

We approach every effluent case in a methodical and a scientific manner. Before submitting a price quote, we require the client to provide us with a sample of their effluent, which we then run through our laboratory to ensure we can treat it effectively. Moreover, for Greenfield projects, we emphasize that the client must supply a synthetically produced effluent sample that is representative of their R&D.

Feasibility Study

A questionnaire is first received where we review the effluent characteristics, compounds present, problems statement and the purpose very well with subsequent calls.

Pilot Plant Study

In cases where the client wants to gain further confidence, we also offer on premise pilot trials for your effluent runs. Our pilot plants range from 1 KLD to 5 KLD capacity.

Treatability Study

Once we are convinced, only after we will request for effluent representative samples to be sent to our lab. Your effluent is subjected to multiple treatability studies and protocols to practically evaluate the best possible outcome and most optimized treatment protocol. A detailed report is tables with complete basic design- PFD, Water Balance, Lab Test Results with budgetary CAPEX and OPEX numbers.

Commercial Quote

Finally a price quote is submitted after completing the treatability studies on your representative sample of effluent, along with PFD/Schematic, Water Balance, best possible commercially viable scheme, with firm CAPEX, OPEX, plant footprint with overall dimensions of key equipment. Page

Awards Wins

It is a long establish fact that a reader distracted

Team Members

It is a long establish fact that a reader distracted

Project Done

It is a long establish fact that a reader distracted

Satisfied clients

It is a long establish fact that a reader distracted